FSO Safer: Oil containment booms being used during ship-to-ship oil transfer

So what exactly are they and how do they work?

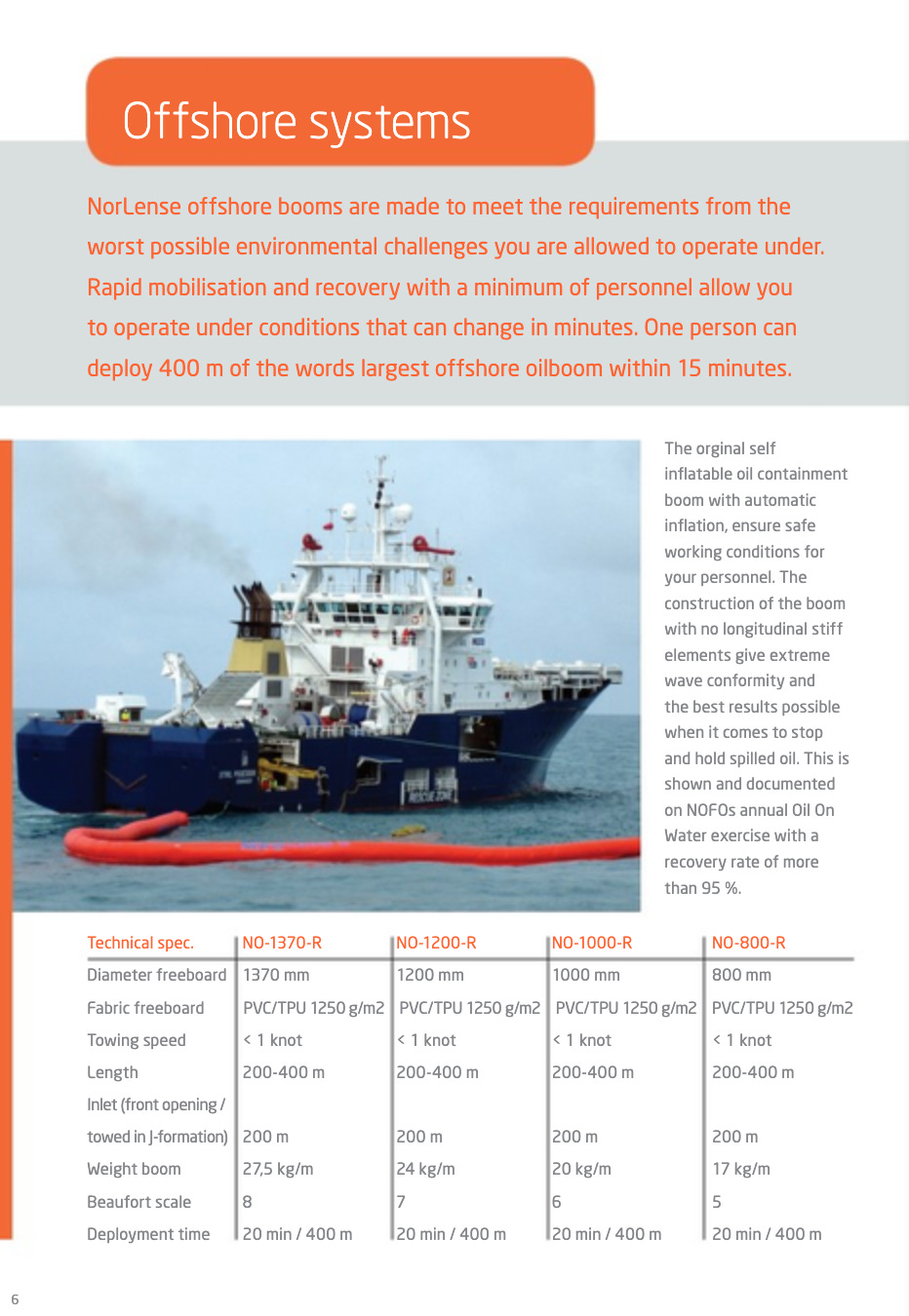

After the engine room of the FSO Safer flooded in May 2020 and took five days for crew and a team of divers to repair the damage, the UN reportedly ordered a one-kilometre inflatable oil containment boom from the Norwegian oil-response equipment supplier Norlense. It was shipped to the area near the Safer but not deployed.

With the ship-to-ship transfer part of the operation having commenced on Tuesday 25th July and expected to take around 19 days, it will get its chance to be used, as anticipated in the UN’s November 2020 Scope of Work document for the Safer operation:

In accordance with the primary mission objective of reducing the risk of a spill from the FSO, it is the intention to provide a continuous oil boom of 1,000 m length encompassing the FSO hull, acting as first defence line if an oil spill should occur. This oil boom will be connected to the bow of the FSO, enabling the boom to follow the weather-vaning of the vessel around the turret anchoring.

And when the International Maritime Organisation (IMO) sent out an appeal in April 2023 to member states for any spare used or near-end of life oil spill equipment for the operation, it listed out a variety of requirements for booms as well as complementary skimmer brushes and storage tanks.

But what exactly are oil containment booms, and how do they work?

A barrier to exit

As the name suggests, oil containment booms are used to contain any oil from a spill and prevent it spreading beyond the confines of the perimeter of the boom; the oil can then be removed either through skimmers (operated on the water), chemical dispersants (dropped from the air) or, most dramatically, burning.

Booms are temporary pieces of equipment which float on the surface of the water and come in a variety of sizes and configurations depending on the conditions present in the water and surrounding environment.

Once installed they can be located in a stationary position surrounding the affected (or anticipated affected) area or moved around to corral or trap the floating oil (because it is less dense than water) into the desired position.

Components of a boom

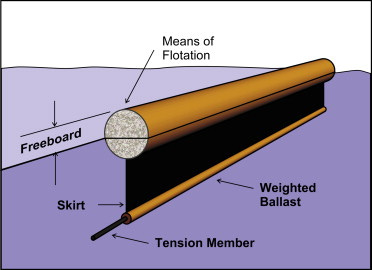

While the below diagram of an inflatable boom is not a replica of a Norlense boom, it does show the key components of a typical oil containment boom.

Freeboard - This sits above the waterline and acts to prevent the waves washing the pollutants over the top and thus out of the perimeter. The booms are made out of a tough PVC material.

Skirt - This is the equivalent of the Freeboard but is positioned under the water instead, to trap any oil being pulled underneath by currents.

Weighted Ballast - This ensures that the Skirt remains taut underwater, acting like an anchor.

Tension Member/Line - Cables and chains provide the boom stability, shape and strength to deal with the sea and weather conditions.

Means of Flotation/Flotation chamber - Booms can be kept afloat either through the use of a solid foam-core material or air-inflatable models (manual or self-inflating); inflatable booms can have higher buoyancy-to-weight ratios compared to more solid booms, which can be an advantage out in open seas.

Lateral connectors - These allow different lengths of booms to be joined together to form an even greater entrapment area. Looking at Norlense’s standard catalogue of booms, which range from 200 metres to 400 metres, unless a bespoke 1 kilometre boom has been manufactured, they would be joined up using the connectors.

According to Norlense, results “from the NOFO Oil-On-Water tests from previous years show that over 90% of the spilled oil was recovered”. Let’s hope that the booms don’t need to be put to the test again here.